Quick Details

Condition: New

Type: Circular

Application: Ore

Place of Origin: Jiangxi, China (Mainland)

Brand Name: Yongsheng

Model Number: 900/1800

Voltage: 220V

Power(W): 3 kw

Dimension(L*W*H): 1800*900*800

Weight: 620 kg

Certification: ISO,CE,ISO9001:2000

Warranty: 1 year

After-sales Service Provided: Engineers available to service machinery overseas

Name: Vibrating screen

Layers: 1 layers sieve

Motor: 2.5 kw

Frequency: 1000 r/min

Color: Customized

small sand washer: Placer gold classifyer

Function: Sand sieving machine

Capacity: Depends on model

Layer: 1-3 Layers

Material: Carbon Steel

Packaging & Delivery

| Packaging Details: | Carton/customized |

|---|

| Delivery Detail: | With 15 days after payment |

|---|

Silica Sand Vibration Screen Sieving Machine Vibro Separator For Sale

Sieving machine also known as vibrating screen which is applied in sand&ore classification by the vibrating of machine body. It largely used in mining industry.

This series vibrating screen with simple structure, and easy to maintenance, reliable to operation, and screen efficiency high. It can desliming, dehydration and removing medium operation for medium-grained material for mining, coal, electricity, construction and chemical materials. And installation of rubber screen is preferred for grading cokes material.

Model | Screen Layers | Screen Area | Feed size | Capacity | Opening size | Frequency | Power | Weight |

| Layers | m2 | mm | t/h | mm | r/min | kw | Kg |

600/1200 | 1 | 1.1 | 40 | 10-20 | 1-15 | 1000 | 2.2 | 350 |

600/1200 | 2 | 1.1 | 40 | 10-20 | 1-15 | 1000 | 2.2 | 360 |

900/1800 | 1 | 1.62 | 60 | 20-25 | 1-25 | 1000 | 2.2 | 550 |

900/1800 | 2 | 1.62 | 60 | 20-30 | 1-25 | 1000 | 3 | 620 |

1250/2500 | 1 | 3.13 | 100 | 150 | 3-30 | 850 | 5.5 | 1100 |

1250/2500 | 2 | 3.13 | 100 | 150 | 3-30 | 850 | 5.5 | 1300 |

1500/3000 | 1 | 4.5 | 150 | 220 | 5-40 | 800 | 7.5 | 2100 |

1500/3000 | 2 | 4.5 | 150 | 250 | 5-40 | 800 | 7.5 | 2300 |

1800/4800 | 1 | 7.5 | 200 | 450 | 6-50 | 360 | 15 | 6000 |

1800/4800 | 2 | 7.5 | 200 | 500 | 6-50 | 360 | 15 | 6300 |

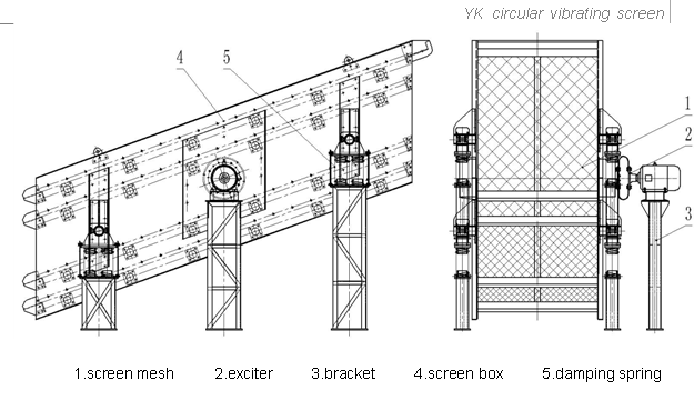

Description&Introduction:

Circular vibrating screen adopts cylinder postures eccentric block to produce strong exciting force.Its main body is connected by high strength screw bolts. A circular, elliptical vibration motion is created in order to sieve the materials efficiently.

Equipped with double vibration motors, which rotate reversely and synchronously. Thus, the excited force by the eccentric block is united in the direction perpendicular to the motor axis while counteracted in the direction parallel to the motor axis, so that the movement trajectory is linear. There is an angle of inclination between two screen decks. Under the function of resultant force generated by exciter force and gravity of materials, these materials are thrown up, leap forward straight ahead along the screen deck, through which the purpose of filter and classification is achieved.

Vibrating screen is mainly used in mining, metallurgy, building material, road, railway, water conservancy and chemical industries. Screening and classifying of medium sized materials like sand, ore granular and cement are very import before further processing of these materials. Also vibrating screen is applied in de-water, de-slime and heavy medium operation.

Function:

Vibrating screen is the most important screening machines primarily utilized in the mineral processing industry. It used to separate feeds containing solid and crushed ores down to approximately 200μm in size, and is applicable to both perfectly wetted and dried feed. The frequency of the screen is mainly controlled by an electromagnetic vibrator which is mounted above and directly connected to the screening surface. The high frequency vibrating screens usually operates at an inclined angle, traditionally varying between 0 to 25 degrees and can go up to a maximum of 45 degrees.

Application:

In mineral processing such as ferrous metals ore (e.g. iron, tin, tungsten, tantalum etc.) and nonferrous metals ores (e.g. lead, zinc, gold, silver and industrial sand etc.), vibrating screens have a crucial role. After the ores get pulverized, vibrating screens such Screens are used as a classifier

which selects materials size that is small enough to enter the next stage for recovery. For example, the closed grinding circuit (e.g. recirculating network with ball mill). Firstly, it screens out the coarse particles and recirculates them back to the grinding mill machine. Then, the fine grain material will be unloaded timely, avoiding over crushing caused by regrinding. The benefits of using vibrating screens in mineral processing can meet the requirement of fineness easily for recovery and is able to achieve a smaller size separation, reducing capacity needed for fine pulverized stage and overall energy consumption. Hence, improving the grade of the final product and providing a better recovery and screening efficiency.

Structuere:

FAQ:

1. Why choose us?

As manufacturer of mining machine, we can supply you with competitive price and overall after sale service.

2. What kind of pre-sale service will you provide?

We will provide raw ore analysis, free procedure design and machine selection guide.

3. How about the discount?

There will be different discount for different models. If you are our returned customer, there will be 5% discount.

4. Are there any further discounts?

If you can recommend new customer to us, we will provide you commissions.

5. How to join us?

Email us and to be our distributor and we can supply you with best price products with ad. cost on our side.

Welcome to our factory and we will provide you more instructions&training!